How to Calibrate Control Valve Which Instrument Is Used

5The instrument will return to weighing after calibration. The calibration range is therefore 0 to 400psig.

How Is Control Valve Calibrated Instrumentation And Control Engineering

Connect a frequency generator at the input terminal of the transmitter.

. On receiving a DVC6200 the instrument mode is In Service. Further set the fine span and make adjustments in the following steps. Adjust pneumatic signal so that the valve closes slowly and stop when the valve fully closed.

Since most valves use a 4 to 20 mA input signal any test tool with an mA output signal can provide the input mA signal to drive the control valve across its operating range. Calibration is one of the primary process used to maintain instrument accuracy. This modal can be closed by pressing the Escape key or activating the close button.

Dynamic error band which is the difference between upscale and downscale plots at any given input signal shall be less than 30 which valve travel. 1Read the manual and install the balance as instructed. A proper risk analysis should be performed when determining the calibration period of instruments.

This is the very first step of the entire process. Move the flapper assembly to the higher value if the output value is saturated to the maximum measurable range. If only the 4-20 mA analog signal is used it may be treated much as an analog transmitter.

2Turn it on and warm up for an hour. 4Then the balance will start automatic internal calibration. To calibrate an instrument involves checking that the out put of the given instrument corresponds to given inputs at several points throughout the calibration range of instruments although the exact procedure may varry from product to product.

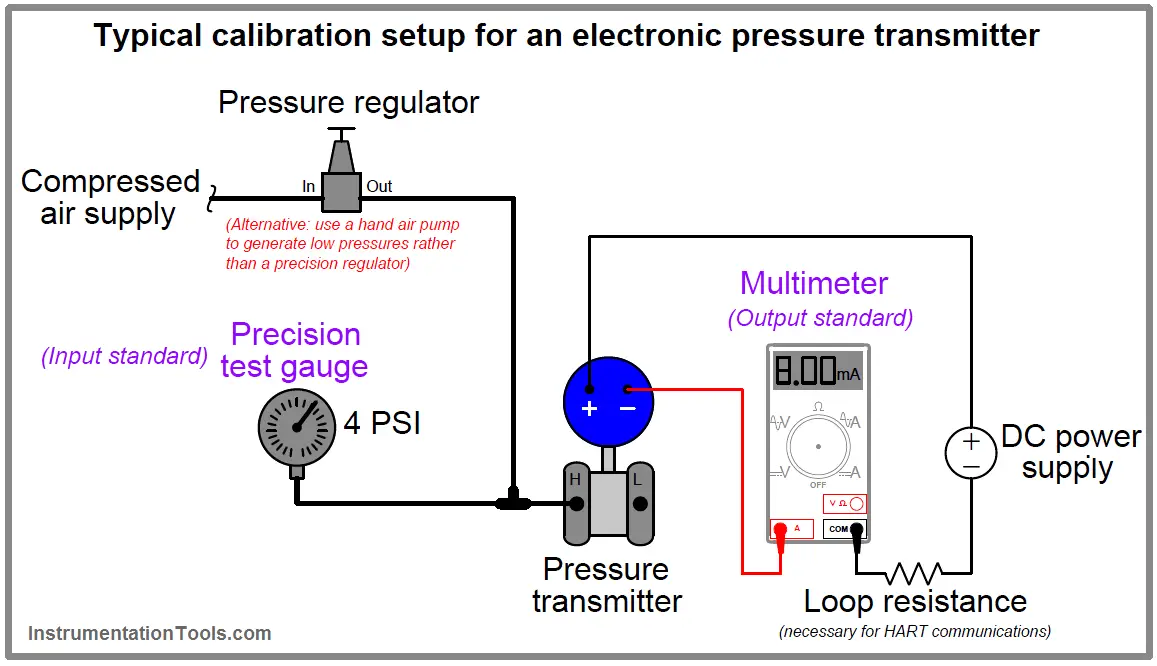

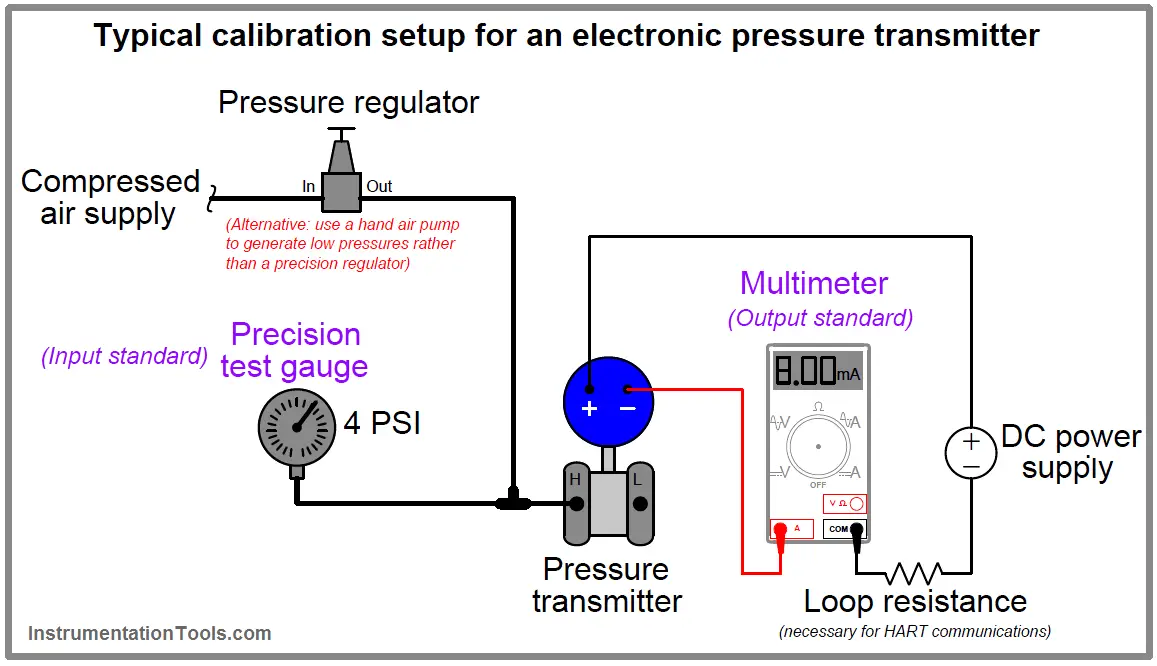

Gently operate the pnuematic pump comparator to achieve the desired set pressure. When applying a 38 mA input signal to a normally closed valve the valve should be hard closed. Before you start the calibration of pressure gauges make sure that the device is placed at a uniform level.

Our valve and instrumentation calibration and maintenance service assures the accuracy of your instruments and consistent process control. For example if an instrument is to be calibrated to measure pressure in the range 0psig to 400psig then LRV 0 and the URV 400psig. Set frequency generator at upper range value and adjust fine span screw till you reach 100 value.

Steps to Calibrate a DVC6200 Controller. The zero value is the lower end of the range or LRV and the upper range value is the URV. The accuracy and reliability of the instruments and devices designed to monitor control and supervise your industrial processes is vital.

Control valve calibration procedure pdf One of the simplest but most important instruments that I encounter which are used not for displaying or monitoring the process but for safety is the pressure safety valvesWhen I was just starting out as a cal tech looking at it installed in a tank makes me curious about its usage. Using the manual zero and span buttons on the transmitter or by digitally setting the PV LRV. Change the control valve from normal to setup mode.

One thing to consider when deciding on a calibration period of any instrument is the cost and consequences if the calibration fails. The calibration approach for a HART instrument will depend on how the transmitter outputs are used. A 3-way valve has two outlet ports and one exhaust or.

Connect the output of the calibrator in series with the transmitter. A 2-way pneumatic valve typically has two outlet ports for instrument air flow in and out. 3When the balance is in the no-load state press the CAL button and CAL-INT will flashing displayed.

In their simplest form there are 2-way 3-way and 4-way pneumatic valves. Move the zero adjustment until the instrument registers accurately at this point. For the calibration of a control valve a loop calibrator or a pressure calibrator can be used between 3-15psiCheck the valve position for 3psi which is to be 0 for a NC type valvesIn such manner check the valve position for various ranges6psi9psi12psi 15psithe valve position should be 0 for 3psi and 50 for 9 psi and completely opened for15psi.

Apply a 4 mA signal to the DVC and power up the HART communicator. Hook up a HART communicator to the DVC6200 in parallel with a 4-20 mA loop across the loop terminals. Apply the lower-range value stimulus to the instrument wait for it to stabilize.

The workbench should be stable for proper operation. Move the flapper assembly to the lower value if the saturated output value is in the minimum measurable range. It is to find a good balance between the costs of the calibration program versus the costs of not calibrating enough.

Note- For English Please enable CCSubtitles and select EnglishDosto is video me maine aapko control valve ke sath lagne wale instruments jaise ki AF. Solenoids are often used in valve pneumatic controls to activate the valve. This completes the calibration process for a.

It should remain closed at 40 mA and move slightly off its seat at 42 mA. Once reach the desired set pressure the PRESSURE RELIEF VALVE should open or The PRESSURE RELIEF VALVE shall open or pop ONLY at the desired set pressure. In order to obtain good process control it is important that the valve can be efficiently and accurately positionedThis video provides an overview on calibrating the Fisher 3582i Positioner on a Fisher 667 Size 30 Actuator.

Hook up the Heart communicator and verify the parameters by referencing data sheet with tag number of the instrument to be calibrated. The method is as follows. Select auto find stop This should require 1 to 5 minutes depending on equipment used and being be calibrated.

The steps involved in the calibration process are as follows. The simplest calibration procedure for an analog linear instrument is the so-called zero-and-span method. Follow these simple steps to get your device up and running.

Valve and Instrumentation Calibration and Maintenance.

Current To Pressure I P Converter Calibration Procedure

Instruments Calibration Procedures Calibration Of Instruments

How Is Control Valve Calibrated Instrumentation And Control Engineering

No comments for "How to Calibrate Control Valve Which Instrument Is Used"

Post a Comment